Steering system

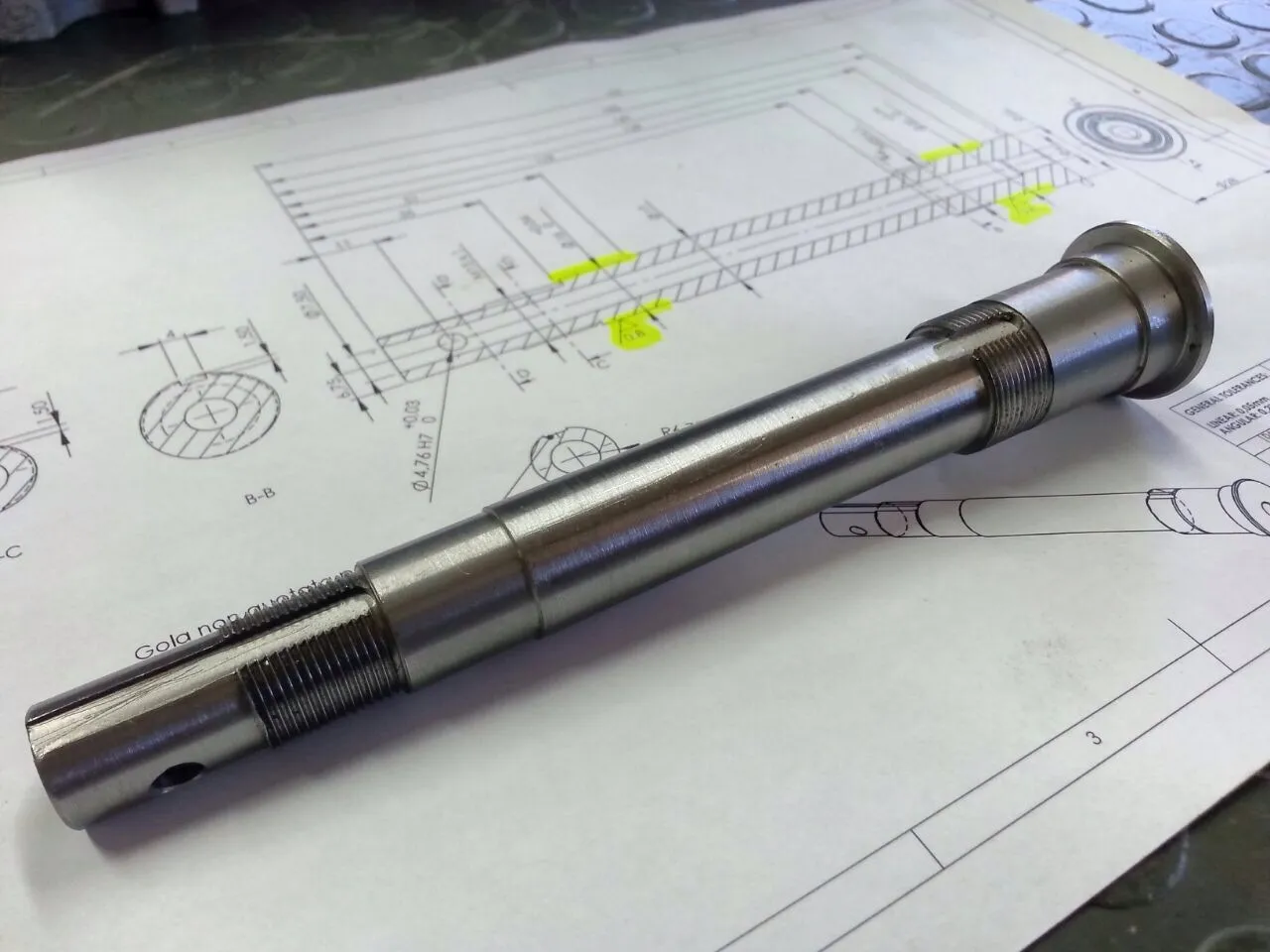

This model of the steering system designed for the FRT’s new car was created in an attempt to minimise cost and weight, striking the right balance between performance, size and ergonomics. To this end, a double universal joint system was used, to ensure a homokinetic motion and to obtain a correct inclination between the steering wheel and the rack; in addition, a collapsible steering column ensures greater driver safety in the event of an accident.

The correct position of the steering axle was obtained through experimental tests conducted by the steering system manager Lamberto Morrocchi. These tests involved all members of the team, using a forklift with the same dimensions as the car. This made it possible to establish the steering wheel height, inclination and distance from the dashboard, while remaining within the limits dictated by the regulations. These parameters were also useful for the development of other assemblies such as the chassis, seat and pedals, which will allow most of the team members to drive comfortably.

This year’s regulations impose a system with only steered front wheels, leaving the freedom to choose the best method to achieve this. The position of the rack was obtained through an intense study that also involved the chassis and suspension designers in order to get the right compromise between the various assemblies, arriving at the conclusion that the best solution was to position the rack forward of the front wheel axle. Other solutions were also evaluated, including a system with a rack set backwards, a hypothesis that was immediately discarded as it would have led to the use of more complex, expensive and weight-consuming solutions.

The transmission ratio between the rack and pinion is designed to have the total exit of the rack with a single turn of the pinion, so as to have good steering control while also being able to keep both hands on the wheel.

All the components have been made and will be assembled on the car this week, so that we can test their function.

We would like to thank:

- Bacci Trasmissioni Meccaniche, a company based in Tavarnelle Val di Pesa (FI); for decades it has been making products for the transmission of racing cars, with particular focus on competitions involving touring cars, prototypes and formula cars

- Histrix, a company based in Pelago (FI); manufactures precision mechanical components exclusively to customer specifications and drawings for the most important companies in the motorbike sector and the most prestigious racing teams

- Th3 Tools for the components and help provided to us.